- Home

- Blog

- Products

- Product description

- Fiber optic splice box

- Optical fiber splice clsoure

- Fiber optic distribution enclosure

- Outdoor Fiber optic distribution box

- Fttx mini closure

- Half type splice closure

- Big capacity splice closure

- MDU distribution box

- Horizontal-splice-closure

- Fiber optic in-line closure

- ADSS/OPGW closure

- Optical fiber splice clsoure

- Fiber optic connecterized box

- Optical fiber splice clsoure

Fiber optic joint closure

Fiber optic cables connect people across the world. Their cable strands run underground, over aerial wires and within buildings alike - with underground sections being more prevalent. But their hair-thin fibers can be fragile; that is why closures play such an important role.

Consider purchasing a closure that matches the cables that make up your network, as well as entrance capacity - the number of cable ports available.

Fiber Optic Joint Closure

Fiber optic cables connect people across the world. Their cable strands run underground, over aerial wires and within buildings alike – with underground sections being more prevalent. But their hair-thin fibers can be fragile; that is why closures play such an important role.

Consider purchasing a closure that matches the cables that make up your network, as well as entrance capacity – the number of cable ports available.

Fiber optic joint closure Basics

Fiber optic cables face extreme environments whether running underground, over aerial wires or across oceans. Although these delicate cables serve end users’ signals efficiently, they are susceptible to loss due to factors like connector or splice loss that reduce signal quality and could ultimately diminish service provision.

Minimizing cable losses requires proper splicing or terminating. Unfortunately, however, this is no simple feat – fiber optic joint closures provide an essential solution in these instances.

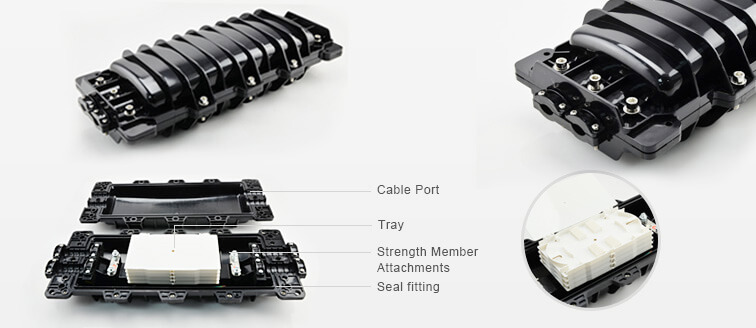

There are various joint closures on the market, but they all share certain common features. For example, they all utilize durable plastics to protect splices and connectors from moisture or water damage and feature special seals to prevent this damage from recurring. In addition, many come equipped with space for cassette storage for spliced fibers to be protected.

Fiber optic splice closures come in dome and inline designs. The former features cable inputs at both ends while the latter has inlets on either end. Their main distinctions lie in terms of shape, size, cable port capacities and splice capacities; some models even incorporate splitters for optical signal splitting capabilities.

Dome fiber optic splice closures feature entrance capacities ranging from 12-288 single or mass fusion splices, making them capable of connecting cable lengths together or joining main and spur cables together. Some versions feature extra ports to add accessories or network equipment.

Fiber optic splice closures can also be used to connect and disconnect cables along a route at any point along its route, and can be mounted on poles, walls or other structures for aerial or underground applications.

Lightwave fiber connectors are commonly used for straight-through or branch connections of overhead, pipeline, direct burial and other structural optical fiber cables. They’re often designed to withstand traffic impacts and extreme weather conditions.

Fiber optic joint closure Seamless Connectivity Solutions

There is a wide selection of fiber optic closures on the market, and selecting one suitable for your network requires careful consideration of various factors like entrance capacity, cable port size and splice tray type. All three factors play an essential part in keeping it running optimally.

The Light Closure is an economical, versatile solution designed for multiple uses. Offering excellent sealing, performance and protection for optical fibre cables junction points, the closure can be installed underground, in manholes or aerially for use across FTTH, transport and utility networks.

This closure features an innovative dome shape that makes it suitable for use both vertically and horizontally, protecting optical fiber cables and splices from environmental stressors such as ground movement, mechanical stress, vibration, impact, chemicals and water. As it’s watertight container with superior resilience to these environmental stresses, this solution offers reliable protection for your optical fiber network.

This closure’s splice trays can accommodate up to 144 fusion splices and splitters without taking up unnecessary space, maximizing network efficiency and performance – an especially useful feature for networks handling heavy volumes of data transmission. Furthermore, this closure serves as a termination point for customer connections.

Hexatronic’s splice closures on this page are ideal for use with FTTH, transport and utility networks. Capable of joining traditional cables, micro duct cables and drop cables with G652 and G657 fibers seamlessly; suitable for ducts, handholes or manholes and easily accessible for inspection and maintenance, their compact design makes these closures straightforward to install in any environment – suitable for aerial hanging applications as well as wall or direct burial bury applications – these closures offer exceptional value.

Fiber optic joint closure Installation

Installing a fiber network requires taking into account several key considerations, including entry port count, entrance capacity, splice tray size and cable capacity within closures. A quality closure should provide ample protection from external elements for all cables connected within its confines and offer adequate housing capacity to accomodate them all.

Selecting the optimal fiber optic closure can be challenging. By considering several key points when making this selection, however, you can ensure your optical fiber communications network runs as efficiently as possible.

An excellent starting point should be ensuring the fiber closure you select is compatible with the cable type being used, to help avoid installation complications in the future. Furthermore, taking into account any cable management features available will save both time and money in the long run by eliminating hassles caused by unnecessary purchases or installations.

Another factor you should take into account when selecting a fiber optic closure system is its level of security. This consideration becomes especially pertinent if your installation may be vulnerable to unauthorized entry – in such a situation, an enclosure should provide both easy accessibility for authorized users while effectively keeping out intruders.

As part of your evaluation of fiber optic closures, make sure they can withstand water and other environmental elements that could potentially cause damage to the cables spliced inside them. It is also crucial that they can withstand fluctuating temperature conditions so they perform as intended in various climates.

The CV019A optical fiber splice enclosure is constructed of high-grade engineering plastic, offering waterproofing, dustproofing and corrosion resistance for outdoor aerial hanging, pole mounting, wall mounting, duct and direct burial applications. Equipped with a 4-splice cassette tray – perfect for managing cables spliced together – as well as armored and non-armored cable support makes this unit suitable for various installations and configurations.

Fiber optic joint closure Maintenance

Optical fiber cable joint closure is used to provide space and protection to fused spliced optical fibre points and cables. These closures may be installed buried underground (manhole), on aerial cables by hanging them from poles or mounted directly to structures such as buildings; there are different models to suit Armoured/Unarmored cables as well as straight or branched configurations. It features a splice organiser inside that protects junction points of optical fibre from environmental factors like vibrations, stress circling or impacts while its water resistant housing will withstand outdoor conditions.

Consider several key criteria when choosing a fiber optic joint closure for your network. The enclosure must withstand vibration, impact, tensile cable distortion and strong temperature changes of your network as well as provide an airtight seal capable of withstanding up to 106kPa of pressure. Furthermore, its outer shell should be made of quality engineering plastic that is rust proof, chemical resistant and anti-aging.

Fiber optic joint closures that can withstand extreme weather and environments will reduce maintenance costs over time, saving on replacement costs as they serve for longer. Furthermore, durable closures allow you to add new connections and expand your fiber network more effectively.

Not only should durability be your main consideration when selecting a fiber optic joint closure, but installation should be too. A suitable closure must be easy to set up in the field and require minimum maintenance, making fiber deployment faster and increasing ROI through decreased costs in terms of labor, materials and service calls. Furthermore, durable closures may reduce service calls while speeding up fiber drop installation times significantly.

Facebook

Twitter

LinkedIn